Get 20% off this month when you try our services!

GEOTHERMAL POWER PLANT OPERATIONS

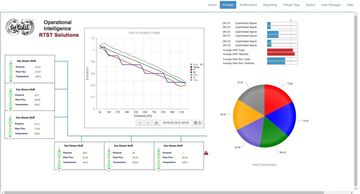

IoT + Optiramp(R) Geothermal Specific Module

Geothermal has been identified as the reliable supply of energy to drive a steam turbine and generate electricity for long term. Converting energy from the steam in earth outer layer, geothermal is renewable and clean energy producer with ability to maintain a consistent production 24 hours a day, 7 days a week and through the year without the dynamics of hourly weather change, or steep curve of activation and de-activation due to daylight. The stability also supports the world class reliability of the power plant, that brings a lot of economic value to the operator.

As a vastly growing renewable source of energy, geothermal possesses the challenge of managing the reservoir to match operation’s generation target. While the generation of megawatt is considerably steady through the year, the hidden risk of high subsurface and surface equipment maintenance cost and untimely drilling campaign can drive the economics of the operations to lower investment return rate or even further down to negative investment side. Over the time, this can be very serious threat to the organization.

Statistics and Control, Inc. in partnership with PT. Alpha Sann Teknika Data, is proud to announce the Geothermal specific real time simulation module. This system is designed to mimic actual condition, with detail parameters from the a single equipment such as valve, fittings, transmitters, to cross country pipeline, elbows, reducers, enlargers as well as the critical equipment such as turbine, pumps, governor valves and generator. The system calculates a continuous iteration of mass balance to create a precise representation or known as digital twin. Given the ability of the simulation, the system can be directed to understand asset character, articulating short and long term production goals, optimizing decline rate and accurately estimating turn-arounds, drilling campaigns, or field expansions.

Utilizing modern Internet of Things (IoT) technology, green field asset will benefit from the accurate representation during engineering phase after completion of G&G development, while brown field asset will mainly benefit from accurate prediction of behavioral change through various operations scheme.

Without huge development effort, our module has been configured and running on both asset types: vapor dominated and water dominated field. Our model can be configured as a superheated or saturated steam reservoir, with pre-set parameters and user defined annual decline rate. Given all features and benefits, the intelligent system will bring a significant advantage through the challenges in the digital era.

Transforming your operations

Jakarta, Indonesia is the central of Optiramp(R) Geothermal Support Center. Contact us directly through email form below for more information. We are glad to set a teleconference, module demonstration and initial study for your asset. This technology is not created for one operation only. It can be adapted to your asset based on organization need and site customization

Integrating subsurface and surface asset

Subsurface Integration

Critical Equipment Monitoring

Being integrated analytics from Geoscience, Reservoir Engineering, Production Engineering, Facilities Engineering, Operations and Maintenance to achieve Business Key Performance Indicators (KPI)

Critical Equipment Monitoring

Critical Equipment Monitoring

Manage critical equipment in precision, early alert system to improve reliability of operations to world class level. Avoid unplanned shutdown will increase revenue and maximize return rate

Unified Platform

Unified Platform

When all data are integrated into a unified platform, the analytics can be made cross discipline, cross functional and cross department to create a comprehensive analytics and more meaningful decisions